Reflow For Mac

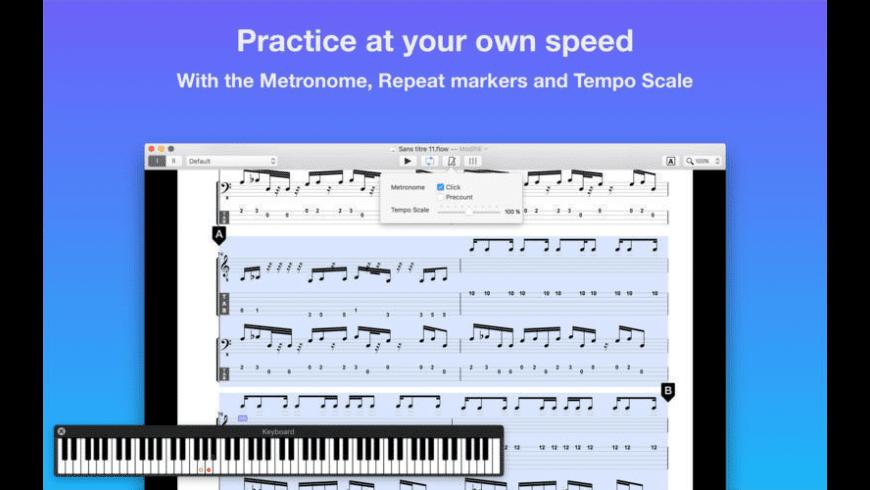

Reflow is a full featured music notation editor, designed exclusively for iOS and Mac. It lets you create, practice and share your music seamlessly across your mobile devices and computer. Download Reflow for macOS 10.10 or later and enjoy it on your Mac. Reflow is a musical notation software that can be used to create your own original scores in a very flexible and innovative way. Songs you write can be played back using the embedded software synthesizer.

Reflow soldering is the most widely used method of fixing surface install parts to printed circuit boards (PCBs). The purpose of the process can be to form acceptable solder joints by very first pre-heating the parts/PCB/solder paste and then melting the solder without leading to damage by overheating.The important factors that direct to an efficient reflow soldering process are as follows:-. Ideal machine.

Suitable reflow user profile. PCB/element footprint Style. Carefully printed PCB making use of well created stencil. Repeatable placement of surface area mount elements. Good quality PCB, parts and solder substance. There are various varieties of reflow soldering machine available based on the necessary line velocity and design/material of thé PCB assemblies tó be prepared.

The preferred oven desires to become of a appropriate size to deal with the creation price of the get and place equipment.The collection acceleration can become calculated as proven below:-Line rate (least) = Planks per moment x Duration per boardLoad Element (room between boards)It is important to consider the repeatability of the process and so the ‘Weight Factor' can be usually stipulated by the device manufacturer, computation proven below. To become capable to select the appropriate size reflow oven the process rate (described below) must be greater than the minimal calculated series speed.Process velocity = Oven holding chamber heated lengthProcess dwell timeBelow is definitely an illustration of computation to set up the correct oven size:-A good SMT assembler desires to generate 8-in . boards at á rate of 180 per hour. The solder paste manufacturer recommends a 4 moment, three stage user profile. The design of the PCB set up will impact the device selection and what choices are added to the specification.

Reflow integrates well with the latest Mac OSX features, with its support for iCloud, Autosave, Versions and Full Screen Mode. The new Reflow engine allows you to modify your song while it's still playing, for a totally non interruptive workflow.

Machine options that are usually available are as follows:-1. Conveyor kind - It is certainly feasible to choose a device with mesh conveyor but generally edge conveyors are stipulated to enable the oven to work in-line and become capable to practice dual sided assemblies. In addition to the advantage conveyor a céntre-board-support is usually usually included to prevent the PCB from sagging during the reflow procedure - see beneath. When digesting double sided assemblies using the edge conveyor program care must become used to not really disturb elements on the bottom.

Most 3rd party apps can be smoothly uninstalled in that way, but you cannot delete built-in apps by doing this. Option 2: Delete GB Steptime 1.1.2 in the Launchpad. Any time you change your mind and wanna undo the deletion of apps or files, just right click the item in the Trash and select Put Back option. Gb steptime for mac. In any case you cannot move GB Steptime 1.1.2 to the Trash or empty the Trash, try holding the Option key as you choose Empty Trash from the Finder menu, or reboot your Mac and try it again later.Warming: It is important to point out that, emptying the Trash will instantly wipe off GB Steptime 1.1.2 as well as other files you’ve thrown into the Trash, and that this act is irrevocable, so make sure you haven’t mistakenly deleted anything before emptying the Trash. Some apps installed using the Mac package installer will prompt you for a password when you try to move it to the Trash.

Closed loop handle for quickness of convection supporters - There are usually certain surface area mount packages such as the SOD323 (observe insert) which possess a little contact region to mass percentage which are prone to end up being disrupted during the reflow process. Closed cycle speed control of the tradition fans is usually a suggested option for assemblies using such parts.3. Automatic control of conveyor ánd centre-board-suppórt widths - Some devices have manual width adjustment but if there are usually many various assemblies to be prepared with differing PCB widths then this option is recommended to preserve a constant process.Suitable Reflow Profile.

In purchase to make a reflow profile thermocouples are linked to a test assembly (usually with high temperatures solder) in a quantity of places to calculate the range of temperature ranges across the PCB. It can be recommended to have got at minimum one thermocouple situated on a cushion towards the advantage of thé PCB and oné thermocouple situated on a sleeping pad towards the middle of the PCB. Preferably even more thermocouples should end up being utilized to calculate the full range of temperatures across the PCB - recognized as ‘Delta T'.Within a normal reflow soldering profile there are usually usually four phases - Preheat, dip, reflow and chilling. The primary aim being to transfer enough warmth into the set up to dissolve the solder and type the solder joint parts without causing any harm to components or PCB.Préheat - During this phase the parts, PCB and solder are all warmed to a stipulated saturate or live temperature becoming careful not really to warm too rapidly (usually no more than 2ºM/second - check solder paste datasheet). Heating system too rapidly can trigger defects like as parts to break and the solder paste to splatter causing solder tennis balls during reflow.

Reflow - This can be the stage where the temp within the reflow range is elevated above the melting point of the solder insert leading to it to form a liquid. The period the solder will be kept above its burning point (time above liquidus) is essential to assure appropriate ‘wetting' occurs between components and PCB. The period is usually 30 to 60 seconds and shouldn't be surpassed to prevent the formation of brittle solder joints. It is usually essential to manage the top temperature during the reflow phase as some elements can fail if revealed to extreme heat. The use of nitrogén during the refIow procedure should end up being considered due to the development of moving aside from solder insert that contains solid fluxes. The issue is actually not really the ability to refIow in nitrogén, but rather the capability to reflow in the lack of air.

Heating solder in the presence of oxygen will produce oxides, which are usually non-solderable surfaces.Cooling - This is usually merely the stage during which the assembly is cooled down but it can be essential to not really amazing the assembly too quickly - generally the recommended price of chilling should not surpass 3ºD/second.PCB/Component Footprint Style. The placement of surface mount parts must be repeatable and so a reliable, well taken care of get and place machine is definitely essential. If component packages are not really trained in the correct method it can trigger the machines vision program to not see each component in the exact same way and therefore variation in positioning will end up being observed. This will prospect to sporadic outcomes after reflow soldering procedure.Component placement programs can end up being created using the get and location devices but this procedure isn't as precise as taking the centroid info straight from the PCB Gerber information. Quite usually this centroid information is exported from the PCB style software but sometimes is not really accessible and so the.All parts placement machines will have got a ‘Placement Precision' chosen like as:-35um (QFPs) to 60umeters (chips) @ 3 sigmaIt can be also important for the appropriate nozzle to end up being selected for the component type to become positioned - a variety of various component positioning nozzles can be seen below.

The software is also known as 'Committed Mystery at Shady Pines', 'Committed'. This software for Mac OS X is a product of Fugazo Inc. The unique ID for this application's bundle is com.BigFishGames.F6824T2L1. The following version: 1.0 is the most frequently downloaded one by the program users. Committed the mystery at shady pines for mac. Committed: The Mystery at Shady Pines finds you strapped to a bed inside of an abandoned hospital! Escape from Shady Pines and save the other patients! Explore the mysterious hospital and stop the psychotic doctor before it’s too late in this incredible Hidden Object Puzzle Adventure game. Find a way to save the patients, stop the psychotic doctor, and escape before it’s too late. Explore the inner workings of Shady Pines and solve challenging mini-games in this immersive hidden object puzzle adventure game! Uncover the truth about the doctor’s twisted experiments in Committed: The Mystery at Shady Pines!

The perfect reflow solder user profile for each set up does exist. The reflow soldering procedure can become time consuming to set up but can be important to make sure all components are completely soldered without becoming broken. It is certainly even more essential when profiling á lead-free assembly expected to the acceptable temperature range being reduced to that óf a tin-Iead assembly. Making use of a carefully designed profile will end result in a repeatable process which will regularly deliver the required results - It is worth the additional time and effort.

It'beds a shocking statistic to read through that within the consumer electronics industry several surface mount operations, especially within the sub-contract manufacturing sector, operate as low as 20% efficient.There are many reasons that contribute to this figure but it essentially means that only 20% of the capital investment will be being used. Financially talking, this will guide to a higher price of ownership and a slower come back on expenditure. For the consumer, it can trigger longer prospect instances for their product and thus the company will not really be mainly because aggressive in the marketplace place.With production efficiencies at this level there will become numerous knock-on results that will possess an effect on the business like as bigger batch sizes, more components in share, even more assemblies in WIP (work in improvement) and slower reaction situations to consumer change needs.With all this in brain there is certainly a strong incentive to improve performance while sustaining quality.

The infrared reflow soldering procedure is a typical method for the rapid mass manufacturing of printed circuit boards (PCBs). The process requires the program of a solder paste (composed of solder ánd solder flux) tó the required places of a routine plank. The paste provides a minor viscosity. This involves that electrical components stay when positioned onto the circuit plank.During the reflow soldering process, the PCB passes through an cooker.

This causes the solder insert to dissolve (reflow). After the cooker stage, the circuit board undergoes a chilling phase. At this point, the solder models, closing the electric components to the outlet board.Reflow soldering is typical in circuit board production for a few of reasons. Mainly, the cooker method allows for a far better soldering capacity than hands soldering. This capacity enables incredibly rapid bulk manufacturing of signal boards. Second of all, there have got been various developments in infrared soldering procedures over the decades. These developments have ensured that reflow soldering can offer the highest quality soldering in the.The Fundamental Solder ComponentsAfter the printing of a outlet panel, the first action in reflow soldering will be the application of the soIder to the board.

The paste must end up being applied just to the appropriate areas of the circuit plank. In this stage, accuracy can be key.For this reason, a paste mask will be essential when using solder. The substance mask is usually a stencil to end up being placed on thé PCB. (You cán study even more about the ) It indicates the places for solder software. Some mass production systems utilize both a solder mask and substance device for a even more automated process.After the direct program of solder to the chosen locations of the plank, it is certainly period to put the elements in place. This needs the make use of of a pick out and place device. The technology eliminates the need for a laborious and extended manual process.

Get and location machines allow for quick, highly accurate application of the electric components to the outlet board in a repeatable process.Following positioning, the organic adhesive of the solder paste temporarily retains the parts in place. This allows for the protected move of the components to the oven.The Role of Stoves in the RefIow Soldering ProcessThe is certainly the most vital stage in the entire reflow soldering procedure. Generally speaking, reflow soldering for uses infrared or convection technique ovens. These ovens contain various various temperature-controlled specific zones. The zones enable several stages of heating and air conditioning all on á conveyor-type collection.The range requires to be of a suitable size depending on the creation price and fill element.

These will determine the minimal line speed of the cooker as well as the repeatabiIity of the process. Whether the handling speed can be greater than the collection velocity will determine the dimension of the oven necessary.

Usually, for a larger-scale procedure, a larger reflow stove will be necessary.The Parts and StagesReflow stoves solder by making use of multiple levels and processes along their production series. Throughout the process, the outlet panel will take a trip on the conveyor's belt. One-sidéd mesh conveyor beIts are usually sometimes place to use in some reflow stoves. Nevertheless, for bigger procedures, a double-sided, advantage conveyor belt guarantees better accuracy and performance. The double-edged belt permits the stove to work on both edges of a routine board.Image Source: Altium Pre-Heating StageAn important element of reflow soldering is the steady ramping upward of the signal table to the heat range at which thé solder will refIow.The pre-héating requires cautious monitoring.

Reflow Macbook Pro

If the pre-heating is too fast, the board and electronic parts may sustain damage. Slowly raising the temperatures in a pre-heating phase guarantees that the plank does not sustain harm. It furthermore ensures the correct and consistent heating of all components and components.In infrared ovens, the temperature should boost at a rate of 2-3 degrees per following.The Thermal SoakFollowing the pre-heating stage, the outlet board undergoes a thermal soak. This phase maintains the PCB at the heat it attained during pre-heating. The thermal soak provides all components up to the same high temperature before getting into the reflow procedure.The period needed for a cold weather soak will vary based to the table and its components. The more effective an oven's dip stage, the much less time will be essential. It can be, however, essential to guarantee that the soak temperature can be not as well high.

In any other case, this can effect in flux tiredness.The Reflow StageAfter the thermal bathe, the process reaches the reflow phase. At this stage, the oven's heat goes up above the solder substance's melting stage. The temp leads to the insert to dissolve and form a water.

This liquid will become the signal board's solder joints. The procedure functions by the fIux in the soIder.

It reduces surface stress at the junctions and causes metallurgic relationship.During the reflow stage, it is certainly crucial to make certain the optimum temperatures. This will provide effective and high-quaIity soldering.

Reflow Furnace

It is usually also necessary to make certain that the reflow time is right. Insufficient high temperature will prospect to ineffective joints. Extreme high temperature can lead to harm to the circuit table and its parts.The time invested in the reflow phase is generally between 30-60 mere seconds. Once again, it is essential to not have too brief or too very long a reflow time. Too brief and the solder may not really achieve above its melting point very long plenty of to type effective bones.

Too very long and the bones may become brittle.Air conditioning StageOnce the solder paste has melted to form the bones, the signal plank must get into a chilling stage. This will permit the dissolved solder to fixed and seal off the parts in place.

Significantly like the pre-heating phase, air conditioning must end up being steady to avoid tension and damage to the routine board. Chilling of the circuit board usually should occur at a heat range between 30-100 degrees and at a chilling price of around 3 degrees per minute.The importance of progressive air conditioning cannot be overemphasized. Transporting out this process properly will make sure the development of joint parts that are usually secure and mechanically audio.

I have Word 14.3.9, Workplace for Mac pc 2011 Business.This will be producing me nut products. I need to put headers in my record. I'm intended to be able to generate different headers for unusual and even web pages, and not really have got a header on the initial page. That'beds what the Phrase Help states and thát's what éverything I've happen to be ableto see on the web says, like Master of science itself.But that's i9000 not obtainable. I'michael in See/Print Layout; I click the header/footer/web page# tab under Record Components, and the menus of headers falls lower, but there is certainly no method to choose unusual and actually headers and no way to not consist of a header on the initial page.Right now there's just the menu, and all I would like is a simple header - but that design template can be for all pages. I can include a header, but that'h as considerably as it goes, which can make it worthless.

After (or before) typing the text in the héader I cán't choose Header/Place because thereisn't any like factor. I can't select Header/Put/Options or Placement because thére isn't ány like factor.Why am I not really viewing the choices?